Molded Fiber Tableware Manufacturing: Machinery & Engineering Support

Why Should We Switch to Molded Fiber Tableware Product?

The world is changing, and so are the products we use in our daily lives. As we become more conscious of the impact our actions have on the environment, there is a growing demand for sustainable alternatives to traditional products. That’s why the molded fiber tableware market is expanding rapidly, and we’re proud to be at the forefront of this revolution.

How Parason Machinery Helps you to Setup Complete Biodegradable Tableware Manufacturing Unite?

At Parason Machinery, we understand the need for eco-friendly solutions, and we’re committed to providing the best machinery and engineering support to meet this demand. Our complete machinery and engineering support include tableware forming machines, trimming machinery, production molds, and stock preparation machinery. With these tools, we can help you produce biodegradable pulp form molded fiber sheet that is both environmentally friendly and cost-effective.

Our tableware forming machines are designed to produce high-quality molded fiber tableware that meets the highest standards of hygiene and durability. Our trimming machinery ensures that your products have a smooth and even finish, while our production molds allow you to create a wide range of shapes and sizes. But it’s not just about the machinery.

At Parason Machinery, we pride ourselves on our engineering support. We work closely with our clients to understand their unique needs and provide tailored solutions that meet their specific requirements. From design and installation to training and maintenance, we’re here to support you every step of the way.

Broadly, the classification of our MoldedFiber Solution and products can be made as under:

- Automated stock preparation system (PLC, SCADA, and DCS System)

- MoldedFiber Forming machine (With Robotic up-gradation)

- R&D Solutions for Product Quality Improvement

- Product Edge Trimming machine

- Production Molds

- Auxiliaries (Vacuum & separator system, air compressor, cooling tower, RO plant, lab instruments, and other necessary equipment)

- Complete Process, Piping, Wiring engineering, Layout, and ISO detailing.

Explore our Integrated solutions for Producing molded fiber products

Molded pulp engineering mainly consists of the process of enhancing the quality of the molded products by improving pulp quality. The raw material used in molded pulp manufacturing is mainly sustainable fibers, recyclable, and compostable fibers.

Molded pulp products or molded fiber products are mainly used for the safe packaging of the food items. The food packaging items such as containers, plates, cups, boxes, wraps, etc. are made from the molded pulp.

Parason Molded Fiber Tableware Manufacturing Machinery

Forming Machine

Parason’s Semiautomatic Forming machine is a hybrid technological solution equipped with forming and in-mold drying stations.

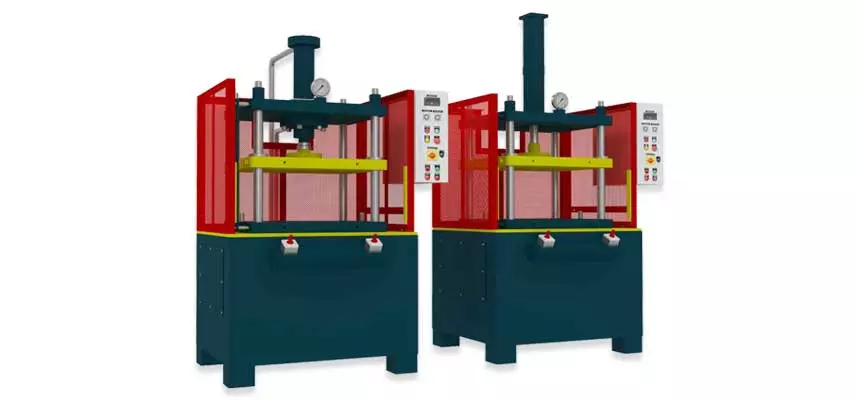

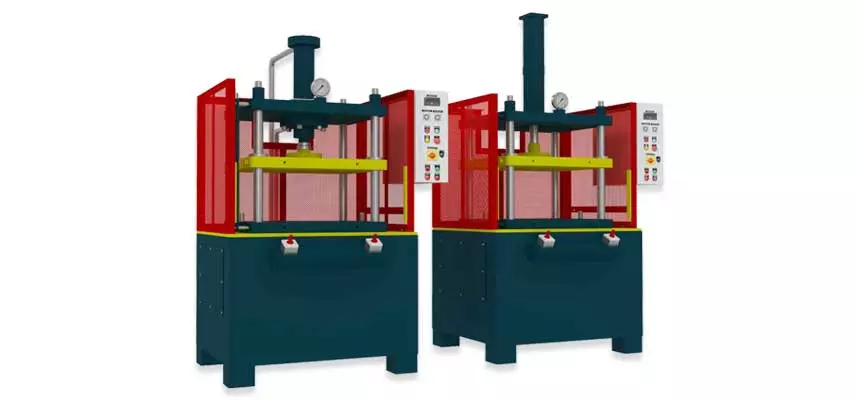

Edge Trimming Machine

Parason Edge Trimming Machine gives the molded fiber products the fine edge finish with dimensional accuracy.

Production Molds

Parason fibre moulding solutions manufacture a various range of disposable tableware products.

Success Stories