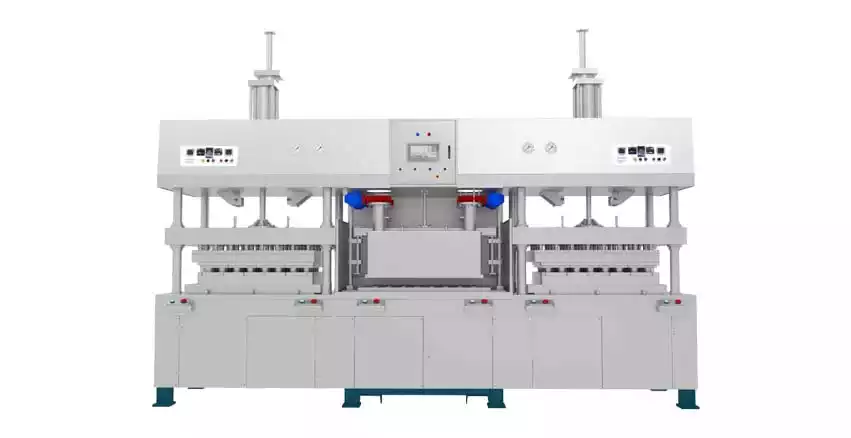

Semi Automatic Forming Machine

Parason’s Semiautomatic Forming machine (PFMV2) is the most advanced technology in this type of forming machine segment. Self-contained technology for forming and drying of products is equipped with a floating distribution type of pulp inlet system which ensures accurate pouring of pulp onto the mold. Benefits in the uniform formation of products throughout the platen.

• Features

- No requirement of back water inlet in machine

- Stationery pulp inlet system

- Platen locking mechanism

- Suitable for manual and robotic operation

Main Specifications:

| Capacity | 500 kgs/day |

| Stations | 1 station |

| Hot press | 2 station |

| Platen size Model 1 | 1100×800 mm |

| Platen size Model 2 | 1000×950 mm |

| Mold heating modes | Electric / Thermal oil |

| Control system | PLC with HMI Screen |

| Product forming type | Floating distribution |

| Product height | Max. 75 mm |

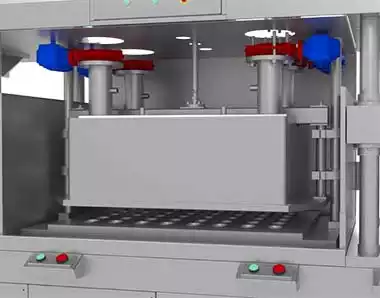

Reciprocating Forming Machine

Parason Reciprocating Forming machine is suitable for critical geometry products with lesser draft angles. Dipping type of formation system ensures proper deposit of pulp in forming cycle.

Features

- Reciprocating (dipping) type forming system

- High pressure shower system for auto cleaning

- Suitable for manual and Robotic Operation

- Insulation gaps in heating platens

Main Specifications

| Capacity | 500 kgs/day |

| Stations | 1 station |

| Hot press | 2 station |

| Platen size Model 1 | 1100×800 mm |

| Platen size Model 2 | 1000×950 mm |

| Mold heating modes | Electric / Thermal oil |

| Control system | PLC with HMI Screen |

| Product forming type | Floating distribution |

| Product height | Max. 75 mm |

Semi Automatic Forming Machine

Enquiry Form

RELATED LINKS