Fiber Saver

Applications & Salient Features

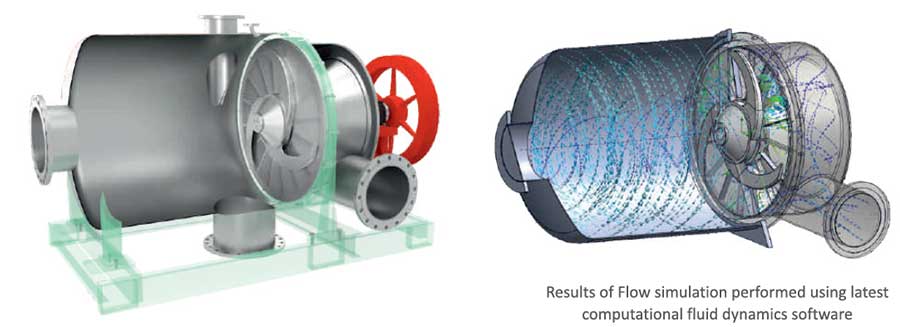

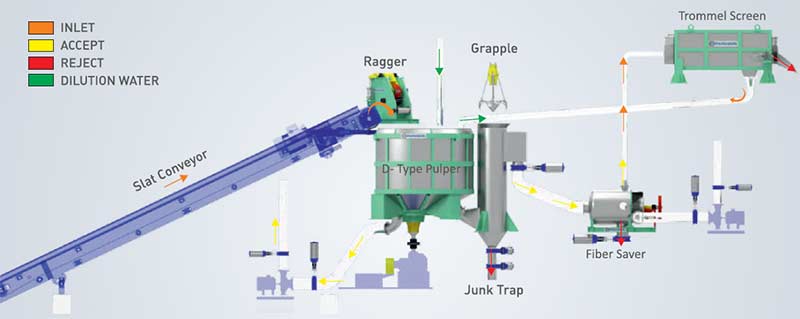

Low Consistency pulper is connected with Fiber Saver and basically, the reject contaminants over the pulper screen plate are treated in fiber saver. The Fiber Saver has the due function of separating plastics and other foreign materials. The Fiber saver screen plate normally has the same perforation as that of the pulper and the impeller rotating against the screen. The impact of the impeller separates the fiber from the rejects and before the heavy rejects dump it is thoroughly washed to recover good fiber hence working most efficiently for fiber recovery.

Advantages

- Uncut contaminants from low-consistency pulper are removed with negligible fiber loss

- The Fiber Saver works as continuous cleaning equipment for the pulper and helps in a throughput increase

- Removal of large foreign contaminants eliminates the risk of pulp jamming in successive operations

- The contaminants discharge cycle can be operated through a PLC-based (time control) panel

Fiber Saver

Enquiry Form

RELATED LINKS