High Consistency Pulper & System

Versatile Equipment For

→ Newsprint mills → Writing & printing mills → Board mills → kraft mills

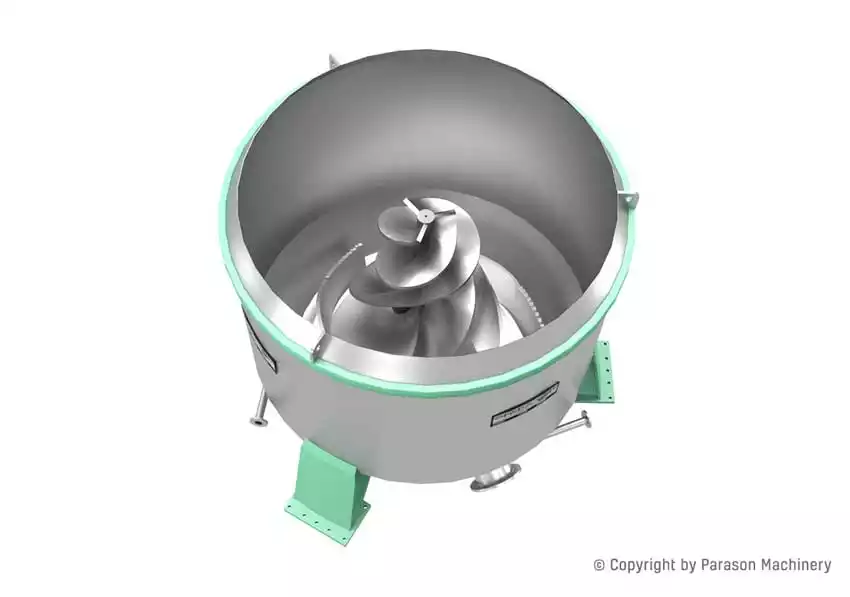

ADVANTAGES OF PARASON CASTED HIGH CONSISTENCY ROTOR

Cast construction

- • Helical Design

- • Strongest Construction

- • Homogenous microstructure from surface to core

Accurate machining

- • Zero eccentricity

- • Perfect right-angle arrangement

Proven technology

- • Possible to slush a wide range of raw materials

- • Help full in Deinking

Austenitic Stainless steel Material of Construction

- • Superior grade

- • Better toughness

- • Wear-resistant

Hardened edges

- • Uniform slushing

- • Long service life Can slush at high consistency

Profile and geometry

- • Perfect engineered contours

- • Unchanged geometry after long use

Balancing

- • Expert computerized system

- • Precision rotation Low power consumption

- Long life

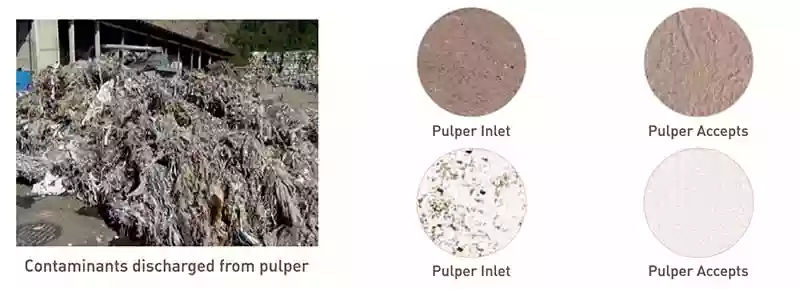

Efficient Removal of Contaminants

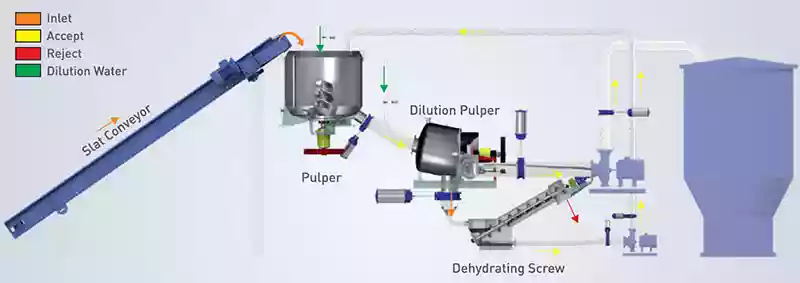

High Consistency pulping system is operated in batch process. The unique design of the rotor creates excellent circulation within the vat and gives good slushing of raw materials, which permits operation at consistency up to 15-16%. The Hi-con Pulper is suitable for all waste paper grades.

The discharge system is designed to discharge the high consistency stock from pulper diluting up to 4% and efficient removal of coarse contaminants. The benefits of high consistency pulper are highly efficient in ink detachment, especially in Writing and Printing grade. Efficient slushing of fibers, gentle removal of contaminants.

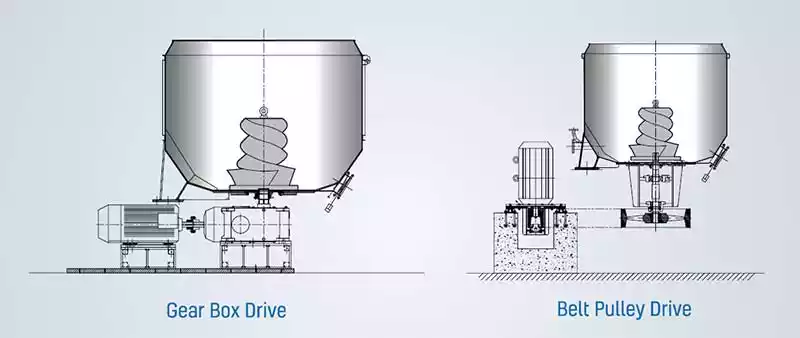

P&I Diagram Of Hi-Consistency Pulper & Loop

Technical Specifications:

| Capacity m3, | 4 | 5 | 6 | 8 | 10 | 12 | 15 | **18 | **22 | **25 | **30 | **35 | **40 | **50 |

| TPD | 30 | 35 | 45 | 55 | 70 | 85 | 110 | 130 | 160 | 180 | 215 | 250 | 280 | 350 |

| Power(kW) | 90 | 100 | 110 | 160 | 200 | 220 | 315 | 335 | 400 | 450 | 550 | 600 | 700 | 800 |

Photos:

Hi-Consistency Pulper & System

Enquiry Form

RELATED LINKS