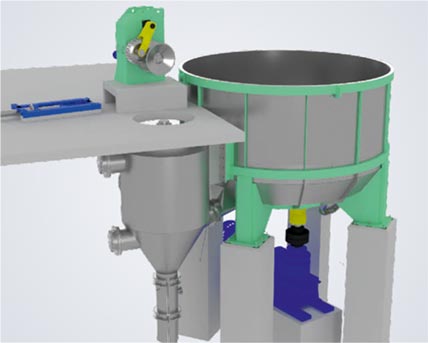

Low Consistency Offset Pulper

Operating Principles

Parason newly developed Offset Pulper which is designed with a combination of double-coned bottom and baffle where the baffle guides the pulp towards the rotor for achieving efficient and extensive slushing. Intensive turbulence is generated on the part of the rotor, whereas low-level turbulence is generated at the baffle which causes the stock to rotate repeatedly thus obtaining excellent quality pulp

The troublefree ragger operation provides reliable operating conditions across large throughput. The combination of double-cone bottom & baffle pushes the core contaminants towards reject discharge.

Application & Features

- – Offset pulping process for uniform pulp

- – Improved throughput

- – Double cone bottom provides excellent slushing

- – Reliable ragger operation and low maintenance costs

- – Improved removal of coarse rejects

- – Specially built rotor for power-efficient pulping

Technical Specifications:

| Capacity m³ | 12 | 16 | 20 | 25 | 32 | 40 |

| TPD | 60 70 | 100 110 | 110 120 | 150 160 | 300 400 | 300 400 |

| Power (kW) | 110 | 150 | 180 | 250 | 355 | 355 |

| Capacity m³ | 52 | 73 | 95 | 120 | 145 | 170 |

| TPD | 400 – 450 | 600 – 650 | 700 – 750 | 900 – 950 | 1100 – 1150 | 1300 – 1400 |

| Power (kW) | 450 | 560 | 710 | 900 | 1100 | 1250 |

OFFSET PULPING LOOP

Enquiry Form

RELATED LINKS