Confiner

PARASON – The Prime source

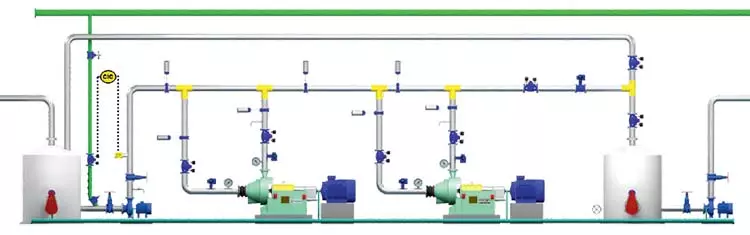

Refining is the backbone in the stock preparation stage as well as paper making. Hence every paper mill is trying to adopt the latest technology in refining. PARASON CONFINER is a modified Conical Refiner designed to enhance the bonding ability of fibers with a minimized freeness drop and minimum decrease of fiber length with low energy consumption and easy maintenance.

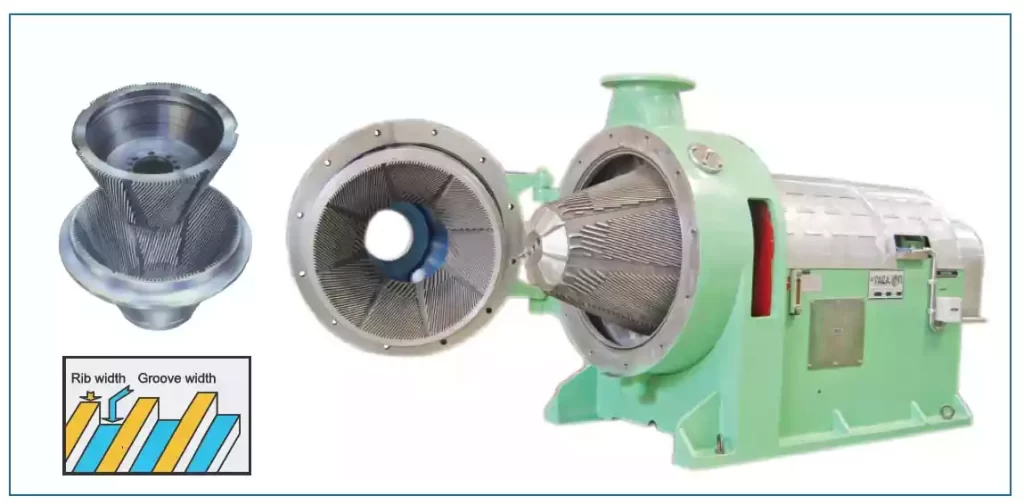

Parason Confiner Fillings

- – Different patterns are available in conical types

- – Patterns manufactured on high precision

- – Confiner tackles manufactured in alloy steel with excellent workmanship

- – Low-intensity refining, uniform refining, best fiber development at lower power consumption

- – Confiner tackles manufacturers in the cast as well as welded design

- – Compact construction reduces floor space requirements

- – Exceptionally low no-load power consumption rises the effective power

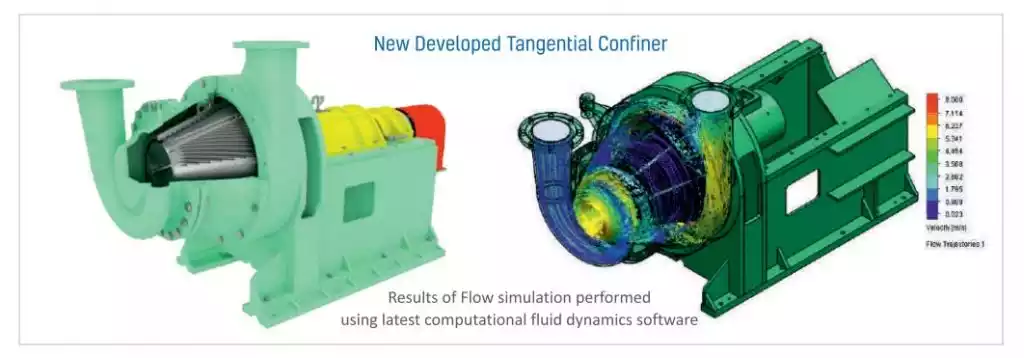

A Novel Introduction to Technology

- – Vortex centrifugal flow

- – Stable gap, Uniform refining

- – No-load power consumption

- – Low-intensity refining

- – Easier dewatering and drying

- – 4-axis patterns generation

- – Cantilever construction

- – A foreign material arrester

- – Higher bearing life

- – Strong and robust construction

Designing Factors

- – Assurance of correct fiber retention time and development of desired fiber properties due to the short shadow cone angle and large refining surface area

- – Easiest filling charge due to cantilever design

- – Loading/Unloading with hydraulic power pack system for fully auto control operation

- – Stable operations and accurate gap control provide stable loading

- – Fast loading/unloading and slow loading/unloading modes of operation

- – Compact construction reduces floor space requirements

- – Exceptionally low/no-load power consumption rises the effective power

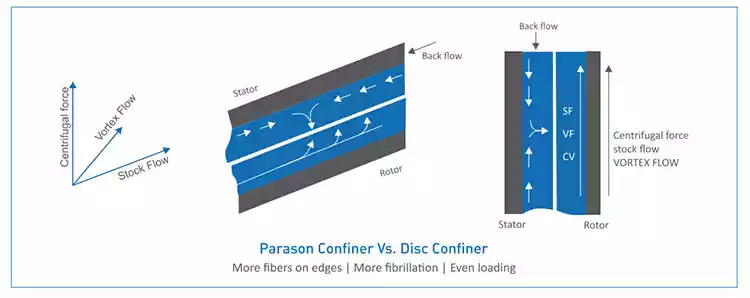

Gentle Fiber Treatment

Geometry of the Parason Confiner is quite different from the conventional Double Disc Refiner. The fiber development (treatment) depends on –

- – Assurance of correct fiber retention time and development of desired fiber properties due to the short shadow cone angle and large refining surface area

- – Easiest filling charge due to cantilever design

- – Loading/Unloading with hydraulic power pack system for fully auto control operation

- – Stable operations and accurate gap control provide stable loading

- – Fast loading/unloading and slow loading/unloading modes of operation

- – Compact construction reduces floor space requirements

- – Exceptionally low/no-load power consumption rises the effective power

Advantages Of Confiner For Paper Making

- – Improved paper quality due to uniform fiber treatment and excellent fiber development

- – Higher paper production and better strength properties due to easier dewatering and drying in paper machines

- – Better retention of fibers and fines

- – Lower energy consumption

- – Minimum process downtime as easy maintenance and quicker change of fillings

General Dimensions:

| Type | Rib Width | Groove Width | P – Parason |

| Microbar Welded PYW PXW |

1.2 1.6 1.2 1.6 |

1.9 2.5 1.9 2.5 |

MB – Extra Low Intensity Refining SW – Low Intensity Refining SW – Low Intensity Refining SW – Low Intensity Refining |

| PSF PSM PSC |

2.0 2.5 3.0 |

3.0 3.5 4.0 |

SF – Short Fiber Fine SM – Short Fiber Medium SC – Short Fiber Coarse |

| PLF PLM PLC |

4.0 4.5 5.5 |

5.0 6.5 7.0 |

LF – Long Fiber Fine LM – Long Fiber Medium LC – Long Fiber Coarse |

| PLF PLM |

4.0 8.0 |

3.0 5.0 |

FS – Trimming Medium TC – Trimming Coarse |

| PLF PLM |

4.0 8.0 |

3.0 5.0 |

FS – Trimming Medium TC – Trimming Coarse |

| PTM PTC |

3.0 4.5 |

7.0 8.5 |

Tm – Trimming Medium TC – Trimming Coarse |

| PMX | 3.5 | 5 | MX – Mixed Fiber |

Technical Data:

| Model | CR-25 | CR-35 | CR-45 | CR-60 | CR-75 | CR-100 | |

| Capacity | TPD | 10-15 | 20-50 | 50-100 | 80-350 | 10-500 | 120-750 |

| Operating Consistency | % | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 |

| Power rating | HP | 25-60 | 90-150 | 150-300 | 350-650 | 500-1000 | 800-2000 |

| Refiner RPM | RPM | 960 | 960 | 960 | 750-960 | 600-750 | 600-750 |

| Inlet stock pressure | Kg/cm2 | 2 | 2 | 2 | 2 | 2 | 2 |

Manufacturing Features:

| Main Body | Cast Iron and stress relieved |

| Refining chamber | S.S.304 |

| Shafts | Precisely ground finished shafts made in SAE-8620 forging case carburized and hardened |

| Parts in contacting stock | Stainless steel casting grade SS-304 |

| Gland system | Stainless steel grade SS-304 gland sealing with the cooling system |

| Coupling | Gear coupling with long slide crowned teeth induction hardened |

| Bearing | Standard make |

| Adjustment of Tackle | By manual or through hydraulic power pack (optional) operated control system |

| Power Saving System | Optional |

| Auto Control System | Optional |

Photos:

Confiner

Enquiry Form