Impellers

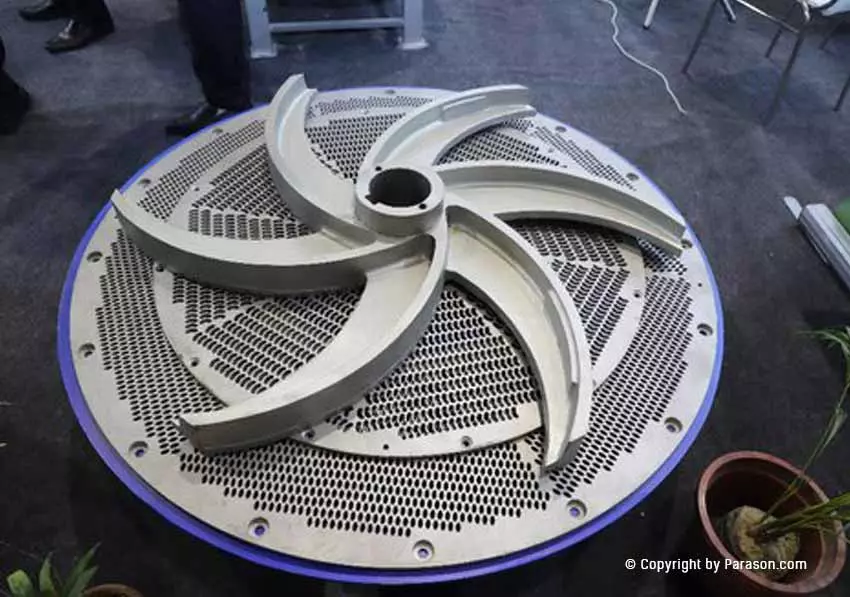

Impellers for Pulper

Hi-Consistency pulper is connected with dilution pulper. The dilution pulper has a due function of separating the plastics and other foreign material as also dilutes the high consistency for stock transfer for further processing. This pulp has 0 6-8 mm drilled screen plate with the impeller rotating against the screen. The impact of the impeller separates the fiber from the rejects, hence working most efficiently for fiber recovery.

Advantages:

- – Uncut contaminates from the Hi-consistency pulper are removed with negligible fiber loss

- – The hi-consistency pulper is ready for the next batch immediately after emptying out

- – The isolating valve isolates the Dilution pulper from the main pulper

- – The dilution pulper works as the first coarse screen, thus reducing a load on the next stage equipment

- – Removal of large foreign contaminants eliminates the risk of pulp jamming in successive operation

Photos:

Enquiry Form

RELATED LINKS