Folded Thickener

Applications & Salient Features

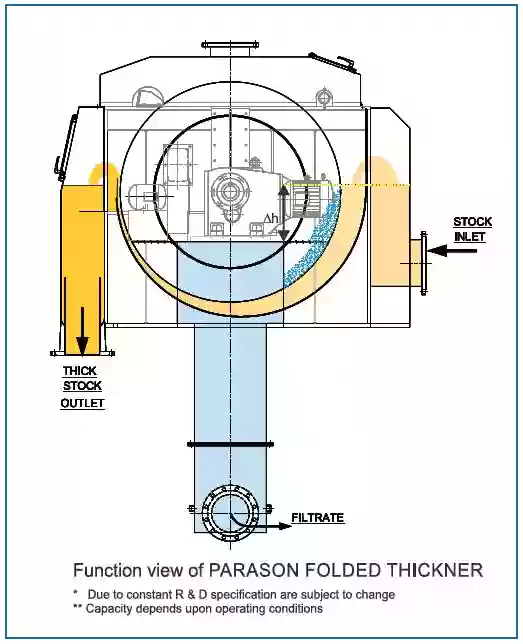

Parason Folded Thickner in comparison to normal thickener provides a larger filtration area. This can translate into smaller space requirements and a higher capacity for specific floor space. The wire clothing is divided into sectors so that each section can be replaced without removing the drum/cylinder.

The stock suspension is fed into the cylinder through an inlet that evenly distributes the stock across the width of the thickener. The water passes through the wire mesh and the fiber mat is formed on the surface of the cylinder. Between the stock level in the vat and the surface of the drain water inside the cylinder, a hydrostatic pressure difference (△h) is produced, which provides continuous filtration. The surface of the wire cloth is cleaned with a shower.

Applications:

- Recycle fiber, chemical, and mechanical pulp

- Effluent sludge, broke in chemical industry

As Washer for

- Deinked Pulp

- Removal of fillers and fines from recycled fiber pulp

Folded Thickener

Enquiry Form

RELATED LINKS