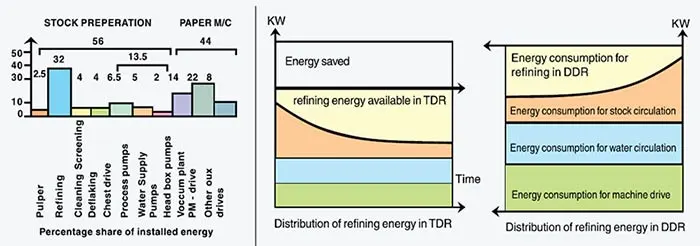

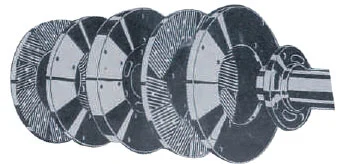

Twin Disc Refiner

Key Features

- – Wide range of metallurgies developed for industry needs

- – Various patterns & bar designs available

- – Custom designed plates are developed in very little time on CNC

- – Continuous developments of new cost-effective material and designs

PARASON – The Prime source for Refiners & Refiner Plates

Compact, sturdy, latest mechanism, and most importantly, the refiner plates bar designs to suit specific applications are special features of Parason TDR. TDR is the result of ACCUMULATED PRECISION making this machine unique in the paper world. Parason refiners have more than 2000 installations within 15 years and this is a direct indicator of its supreme performance.

Further Refining of Refiners

The inclusion of splined shaft technology in Parason TDR permits rotor movement with longer force resulting in uniform floating conditions under stock pressure of 1-2 kg/cm2.

The use of unique and high technology of centrifugally cast martensitic stainless steel shaft sleeves offers maintenance-free working for years.

Parason TDR

- – Rotor 60% lighter

- – 180% larger opening

- – No bolting on surface

- – No bolting on surface

- – Large refining area

- – Saves energy by min. 20%

- – Low cost per ton

Exclusive Features

- – Replace gear coupling with the tyre coupling

- – Sturdy and speedy operation

- – Consumes less power

- – Virtually maintenance-free operation

- – Uniform wear of plates on both faces is achieved

Conventional DDR

- – Heavy rotor, poor life

- – Bolts on bar surface-reduced refining area

- – On the run breakages occur

- – Higher energy consumption

- – More downtime for plate change

Splined Shaft

Splined shaft technology has enabled the reduction of the weight of shaft assembly. Parason TDR is manufactured with the splined shaft to achieve easy movement flotation of the rotor. Uniform wear of discs on both faces.

A Unique Schenck German Analyzer to Analyze

- Spectrum of frequency

- Tracking

- Transfer

- Balancing

- Alignment

- Bearing Vibration

- Bearing Condition

- Shaft Vibration

- Shaft Vibration Sumac

- Temperature

- Sound

- Axial Position

- Process Parameter

- Oscilloscope

- Ultramodern Technology

- Analysis of Overall Evaluation

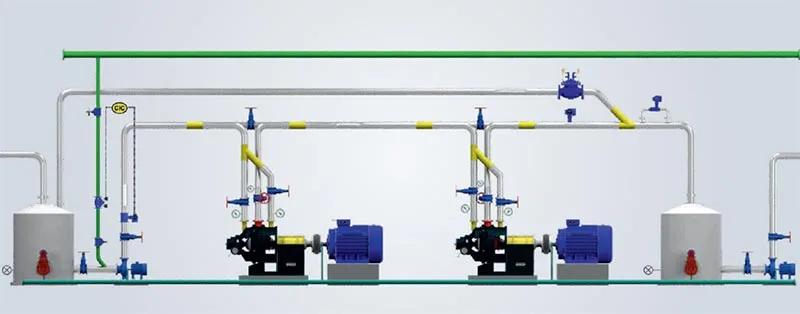

Automation System

Special feature to operate refiner with full auto control mechanism with SP (Set Point) feature saves power with uniform refining.

Oil Bath

This is the only system that provides positive lubrication to the bearings. The continuous feeding of oil ensures soft, smooth, trouble-free & vibration-less operation of Parason Refiners.

Main Specifications:

| Type | A mm | B mm | C mm | D mm | E mm | F mm | G mm | H mm | Disc mm |

|---|---|---|---|---|---|---|---|---|---|

| TDR – 13 | 1325 | 470 | 235 | 750 | 650 | 600 | 530 | 340 | 330 |

| TDR – 17 | 1455 | 520 | 240 | 795 | 745 | 760 | 620 | 410 | 420 |

| TDR – 21 | 1660 | 636 | 260 | 1000 | 900 | 930 | 760 | 500 | 508 |

| TDR – 24 | 1700 | 665 | 250 | 1000 | 1000 | 1035 | 760 | 5000 | 610 |

| TDR – 26 | 2250 | 800 | 300 | 1300 | 1250 | 1095 | 935 | 650 | 660 |

| TDR – 30 | 2250 | 800 | 300 | 1300 | 1250 | 1095 | 935 | 650 | 762 |

| TDR – 34 | 2750 | 950 | 350 | 1600 | 1500 | 1150 | 1200 | 750 | 864 |

| TDR – 38 | 2750 | 950 | 350 | 1600 | 1500 | 1150 | 1200 | 750 | 965 |

Technical Data:

| Model | *TDR-13 | TDR-17 | TDR-21 | TDR-24 | TDR-26 | TDR-30 | TDR-34 | TDR-38 | |

|---|---|---|---|---|---|---|---|---|---|

| Hydraulic Capacity | TPD | 10-15 | 15-45 | 20-70 | 40-140 | 80-140 | 80-200 | 120-250 | 140-400 |

| Consistency | % | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 |

| Motor Rating | Hp | 30-60 | 100-150 | 200-300 | 350-450 | 500-550 | 600-650 | 900-1200 | 900-1200 |

| Refiner Speed | RPM | 960 | 960 | 960 | 720 | 720 | 600 | 600 | 525 |

| Stock Inlet Pressure | (Kg/cm2) | 1.5-2.0 | 1.5-2.0 | 1.5-2.0 | 1.5-2.0 | 1.5-2.0 | 1.5-2.0 | 1.5-2.0 | 1.5-2.0 |

| Appox. Weight | Kg | 500 | 1200 | 1600 | 2500 | 3000 | 3000 | 4500 | 5500 |

Manufacturing Features:

| Cylinder Housing | S.G.Iron (IS-1865-1974) |

| Main Body | M.S. fabricated and stress relieved |

| Shafts | Precisely ground finished splined shafts made in SAE — 8620 forgings case carburized and hardened. |

| Parts Contacting stock | Stainless Steel casting grade SS-304 |

| Packing box system | Stainless Steel grade SS-304 gland sealing with cooling system |

| Coupling | Tyre and Geared |

| Bearings | Standard make |

| Adjustment of disc | By manual for auto-operated control system panel with dual speed gear motor. |

| Auto Control system | Optional |

Photos:

Twin Disc Refiner

Enquiry Form