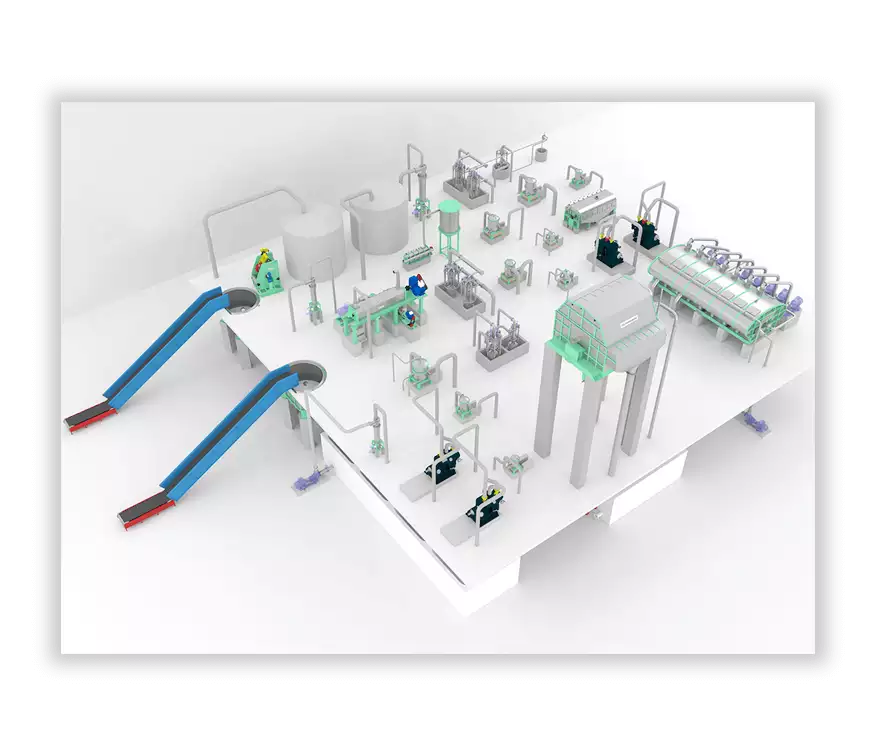

Parason Kraft Paper Manufacturing Machinery and engineering solutions

The market for recyclable kraft paper and boards is sustainably growing; as it a recyclable and renewable, it is becoming irreplaceable as a packing solution. With growingindustries, the demand for kraft board containers is increasing.

Parason Machinery is a perfect partner for your sustainable and efficient kraft paper and board manufacturing. We offer precisely customised kraft paper manufacturing solutions with machinery and end-to-end engineering solutions.

New Installation

We excel in turnkey projects and are responsible for setting up an entire plant from installation to final commissioning.

Capacity expansion & Rebuilding

Our paper machine rebuild and mill capacity expansion help you add new grades of paper, reduce operational costs, enhance operational safety, and achieve your market expansion target.

Manufacture high-quality kraft paper and board with optimised operational cost with Parason’s machinery and engineering solutions

Manufacturing kraft boards with production packing grades and low weight maintaining the strength of paper has always been challenging for manufacturers of kraft paper. You can tackle this challenge with Parason pulping, stock preparation machinery, and engineering services. Parason-integrated kraft paper manufacturing facilities include efficient pulp and stock preparation machinery, a dispersion system, and a final paper machine. With the integration of this, you can develop an efficient fibre line, and the paper-making unit offers:

- Minimised energy consumption

- Enhance the paper quality

- Less water consumption

- An integrated system helps reduce maintenance cost

Explore Our range of Complete Fibre lines and paper-making solutions for Kraft paper manufacturing

Parason Pulping Machinery for Kraft Paper

Low Consistency pulper

Very suitable for furnishing of OCC, AOCC, Box Board separate the reject and fiber.

Inclined trommel Screen

To lessen the contaminant load on FiberSaver(PFS), the light rejects normally directed to Trommel Screen.

Fiber Saver

The Fiber Saver has the due function of separating plastics and other foreign materials.

Pulping Equipment for Kraft Paper

Pulp Cleaning machinery

Course Screening

Turbo Separator

for pulp strainers with a high trash and flake content like recycled paper

Fractionator

separates the fibers mainly by fiber length and is fitted with a hole or slot type baskets

Pulp Thickening Machinery

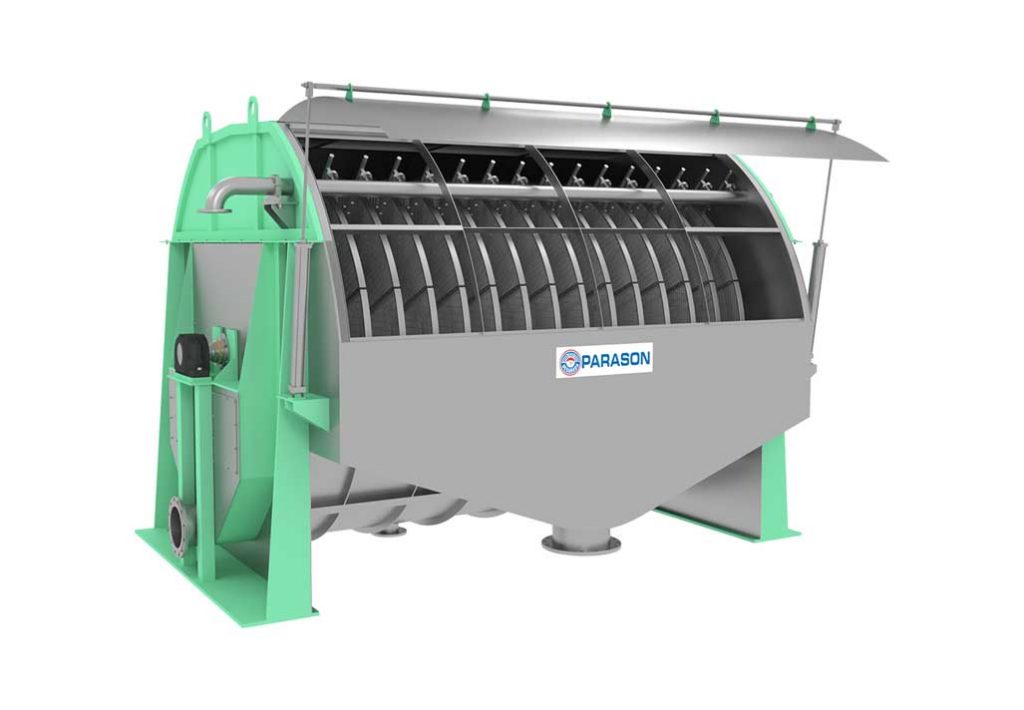

Gravity Disc Thickener

The Gravity Disc Thickener is a compact and virtually maintenance-free, Gravity Thickener can be adjusted according to process conditions such as throughput and inlet consistency. The pulp suspension is fed at a consistency of 0.9% to 2.5% to the inlet chamber into the vat in the same direction as disc rotation.

Thickening capacity is ensured by the number of discs installed in the center shaft. The thickener vat level and outlet consistency are controlled by thickener speed through VFD.

The filtrate is discharged either at one or both shafts ends by gravity, depending on the thickener size. Gravity Thickener permits the installation of a large dewatering area in minimum floor space.

Refining Machinery

Twin Disk Refiner

for pulp strainers with a high trash and flake content like recycled paper

Approach flow machinery for Kraft Paper manufacturing

We offer machinery for approach flow that gives refined pulp with required consistency to manufacture kraft paper, with minimal fibre loss.

Parason Headbox

Parason specialized Hydraulic Headbox is designed for high-speed operations of paper machines. Hydraulic headboxes are designed for twin-wire forming.

Parason Pressurized headbox is constructed skillfully at our manufacturing unit. The pressurized headbox is operated by the pressure of the air. The pond level is maintained at a certain point. Above that level, it contains pressurized air.