Complete Process Guide: How to Set up a “paper mill Plant” Engineering and Commissioning

Looking for a reliable partner to set up a paper mill?

From basic questions to complex compliance inquiries about the Paper Mill Plant, we’re here to help you. Contact us today!

Paper Mill Plant Related Machinery List – Pulping, Cleaning, Screening, Dispersion System, Deinking, Thickening, Refining, Deflaker, Agitation, Reject-handling, Effluent Treatment Plant, Headbox

While planning to set up a paper mill Plant, after selecting the most suitable location for the mill and finalizing the paper grade to be produced; the further process of commissioning of paper mill project becomes more complex and demands a long time, various engineering works and patients.

After reading this guide you would get a roadmap idea for various stages in setting up a paper mill factory and required basic plant engineering works.

Pre-Project Activities to set up a Paper Mill Factory/Paper Mill Plant

Selection of Paper Grade to Produce –

In the market, there are numerous varieties and grades of paper. Each of them requires different machinery and has a different manufacturing process.

Choosing your end product is the very primary thing and can be a game maker, you have to consider various aspects while doing research on it. Following are some key aspects that you have to go through while selecting your paper grade to be produced.

Market Demand:

Conduct market research to learn about the demand for various paper grades in various markets, trades, and consumer groups. You may also go to distributors of paper to learn about market trends, such as which grade of paper is most in demand.

Raw Materials Availability:

Consider the availability and price of raw resources such as pulp, fibers, and chemicals need for that particular paper manufacturing.

Manufacturing Expertise:

Running a successful paper mill Plant also requires a competent team of engineers and consultants. Determine the level of expertise of your team, provide them the necessary training, and employ an experienced team with related experience.

Competition:

Find unique selling propositions by researching rivals, market share, and price.

Profitability:

Analysis of possible profitability based on production costs, market prices, and profit margins.

Selection of Location for Paper Mill Plant

Availability of Raw Materials:

When considering a suitable site for establishing a paper manufacturing plant, it is imperative to prioritize proximity to a reliable and cost-effective source of raw materials, including but not limited to wood, pulp, or recycled paper. The implementation of this strategy leads to a reduction in transportation expenses and guarantees a dependable supply chain.

Transportation and Logistics:

In the realm of paper industry operations, it is imperative to assess the accessibility of transportation infrastructure, encompassing the likes of roadways, railways, and ports. This evaluation is crucial in ensuring the smooth and efficient transportation and logistics of paper products. An optimal geographical location facilitates streamlined transportation of inputs, outputs, and resources.

Labour Force Availability:

The evaluation of labour force availability is a crucial aspect when selecting a location for paper industry operations. It is essential to assess the availability of a skilled and qualified labour force in the chosen location. It is imperative to take into account the demographics of the surrounding community, as well as the presence of academic institutions and vocational training centres that can furnish a labour pool with pertinent knowledge and skills.

Market Accessibility:

When evaluating market accessibility, it is imperative to take into account the proximity to the intended markets and clientele. Proximity to key customers is a strategic advantage that can result in reduced transportation expenses and improved delivery timeframes, ultimately enhancing customer service levels.

Procurement of stock preparation and paper machinery, auxiliary equipment and basic engineering processes

After the selection of end product and raw material, further technical aspects critically rely on these things. At this stage, exploring a reliable supplier of pulp and paper machinery is needed.

Selection of a good Pulp and paper machinery manufacturer and supplier

As the installation and commissioning of paper mill Plant is a technically complex process, and required various engineering operations like raw material analysis, creating 2D and 3D layout paper mill, and mass balancing; selecting a machinery supplier partner with all this expertise and proven track record is very important to a successful but smooth commissioning of your paper mill project.

Following are significance of choosing the right partner for your paper mill project and provides insights into the essential factors to consider during the selection process.

Availability of All required pulping and paper machinery:

It is essential to make sure that the selected partner has all the required machinery availability for your paper mill. The equipment required for diverse paper manufacturing processes comprises pulping, screening, bleaching, drying, and finishing. Having a single supplier for all the required machinery streamlines the procurement process and ensures compatibility and efficient integration of equipment.

Reliability of Engineering Support:

During the installation and commissioning phase of your paper mill, reliable engineering support is crucial. The machinery manufacturer and supplier should have a dedicated team of engineers who can provide technical assistance, troubleshoot issues, and offer guidance throughout the project. Their expertise and prompt support can significantly minimize downtime and optimize the mill’s performance.

Good Record of After-Sales Service:

Continues upgradation and maintenance play a vital role in the long-term success of a paper mill. Choose a machinery manufacturer and supplier known for their commitment to after-sales support. This includes timely maintenance, spare parts availability, and assistance with any operational challenges that may arise. A partner with a good record of after-sales service ensures uninterrupted production and maximizes the lifespan of your machinery.

Technical Expertise:

The installation and commissioning of a paper mill plant involve intricate engineering operations. It is essential to collaborate with a machinery manufacturer and supplier who possesses a deep understanding of the pulp and paper industry. Look for a partner with extensive technical expertise in designing, manufacturing, and delivering machinery specifically tailored to the requirements of a paper mill.

Proven Track Record:

Experience matters when it comes to setting up a paper mill Plant. A machinery manufacturer and supplier with a proven track record demonstrate their ability to successfully deliver projects and meet customer expectations. Research the company’s history, explore their portfolio, and inquire about their past projects to evaluate their performance and reliability. Additionally, consider requesting records or testimonials from commissioned paper mills that have worked with the selected partner.

Basic Engineering processes to set up a paper mill

Stock Preparation and Equipment Sizing:

On the basis of raw material to be used for production and the targeted production capacity e.g. 100-1,000 TPD (Tones per Day) your machinery manufacturer and supplier partner will provide you with a primary techno commercial offer.

Ideally, along with commercial things, this primary offer includes the sizes and capacities of all the stock preparation machinery like pulper, refineries, pulp screening and screening machinery, approach flow systems, and paper machinery sections like pressing, drying sizing, and calendaring sections.

Conceptual plant layout:

The layout of a paper mill Plant or process line is a crucial step that forms the foundation for subsequent engineering activities. Several factors need to be considered to develop an optimal layout, including available space, existing equipment, efficient material flow, maintenance access, minimal piping and ducting requirements, and optimized building size.

Load plans are essential documents for civil engineering, providing information for static and dynamic calculations of the building and machine track. This includes equipment loads, pipe system loads, paper machine loads, earthquake factors, and main openings.

Mass Balance of Plant:

The overall efficiency and cost-effectiveness of a paper mill depend on the interconnectedness of its systems. Achieving an optimal solution requires a comprehensive understanding of the mill’s energy, raw material, water, and effluent balances.

By analyzing these balances and defining the interfaces between various sections, such as stock preparation, wet-end process, paper machine, auxiliaries, effluent plant, and power plant, the best configuration for the Balance of Plant (BoP) can be determined. This ensures efficient integration and operation of the different sections within the mill.

Process and Instrumentation Diagram:

The close relationship between process engineering and automation engineering is evident through their shared use of equipment and resources. By utilizing a single database with distinct templates for automation and engineering, both departments can benefit from streamlined processes, improved data quality, and reduced errors. This approach allows for efficient data input, leading to a shorter overall engineering period and enhanced project outcomes.

3D Plant Layout and Detailed Engineering:

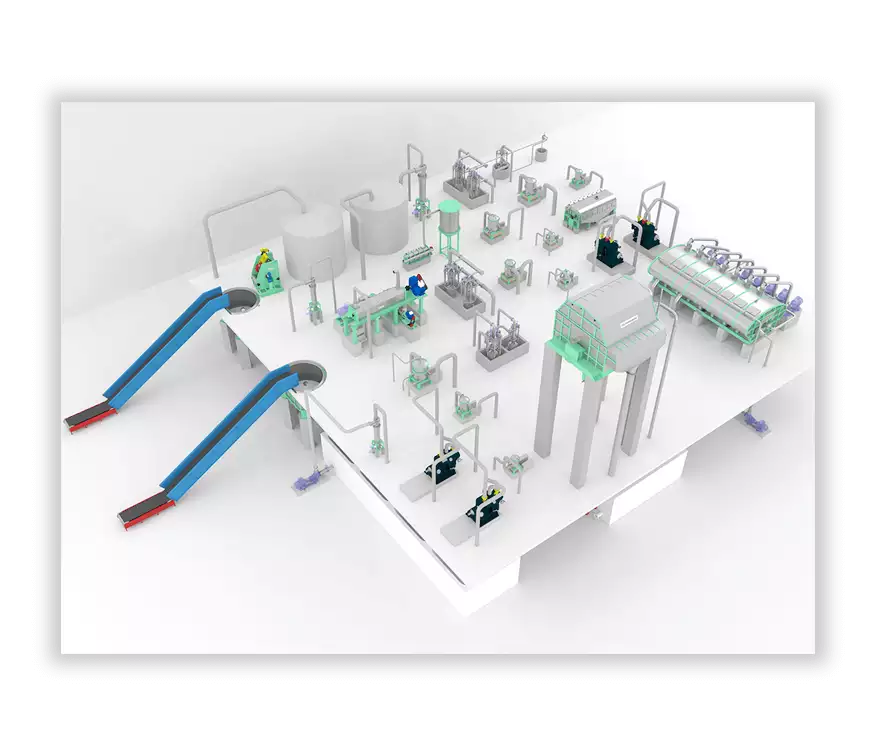

To streamline the procurement, engineering, and installation process, a cutting-edge 3D plant model is utilized. This model encompasses the entire machinery, piping, ducting, steelwork, and main cable trays.

3D Plant Layout of a Stock Preparation System

By integrating the design models of the machinery within the plant model through an interface, a comprehensive 3D representation of the paper mill plant can be achieved. This approach allows all engineering disciplines to collaborate from the project’s inception, facilitating efficient document generation for third parties involved, such as civil contractors.

Civil Foundation Plan:

In civil detail engineering for a paper mill, plant foundation plans are essential. These plans include building constructions, machine and equipment placement with dimensioned foundation bases and anchor bolt recesses, embedded plate location and size, drive foundations, openings in floors, walls, and roofs, walkways and platforms, and floor drainage. These details ensure the proper installation and functioning of machinery and infrastructure within the paper mill.

Piping:

In a paper mill, the machine equipment requires a network of pipe systems to connect them. Compliance with local regulations, such as the Pressure Equipment Directive, and mill standards is essential. Special pipes, like steam pipes, require stress calculations to meet regulatory requirements. The output of piping engineering includes isometric drawings, bill of materials, and drawings for piping supports. The number of pipelines can vary, ranging from approximately 200 for a tissue line to up to 8000 for a newsprint mill with deinked pulp (DIP).

Final Installation and Commissioning of Paper Mill:

After all the basic plant engineering things plant, the actual setting up of the pulp mill starts by the pulp and paper machinery manufacturer and supplier.

Integration of Stock Preparation System:

The stock preparation system plays a vital role in transforming raw materials into pulp, which is the foundation for paper production. During installation, the stock preparation system’s equipment, such as pulpers, cleaners, screens, and refiners, must be properly integrated and aligned. This process ensures the efficient flow of materials and optimal performance of the system.

Approach Flow System Optimization:

The approach flow system controls the consistency and cleanliness of the pulp as it enters the paper machine. It includes processes such as dilution, screening, and cleaning. During installation and commissioning, the approach flow system’s components, including pumps, screens, and piping, must be meticulously installed and calibrated. Proper alignment and optimization of the system ensure consistent pulp quality and minimize operational issues.

Paper Machinery Installation:

The paper machinery encompasses a range of equipment, including the forming section, press section, dryer section, and calendar. Each component must be carefully installed, aligned, and connected to ensure smooth paper production. During this phase, proper adjustment of tension, alignment of rolls, and calibration of control systems are critical to achieving the desired paper properties and production efficiency.

Setting up a paper mill Plant is a complex and time-consuming process that requires careful planning and execution. This guide has provided valuable insights into the crucial aspects of selecting the paper grade, choosing the right location, and procuring the necessary machinery and equipment. By considering factors such as market demand, raw material availability, manufacturing expertise, competition, profitability, and technical support, you can make informed decisions to ensure the success of your paper mill project. Furthermore, the importance of proper engineering processes, including stock preparation optimization, approach flow system integration, and paper machinery installation, has been emphasized. By following these guidelines, you can lay a strong foundation for a productive and profitable paper mill.

Looking for a reliable partner to set up a paper mill?

From basic questions to complex compliance inquiries about the Paper Mill , we’re here to help you. Contact us today!

Share Enquiry Here

Looking for a reliable partner to set up a paper mill?

From basic questions to complex compliance inquiries about the Paper Mill , we’re here to help you. Contact us today!

Paper Mill Plant Related Machinery List –