Sugarcane Bagasse Plate Making Machine & Raw Materials

Looking for a reliable partner to set up a Sugarcane Bagasse Plate Making Plant?

From basic questions to complex compliance inquiries about the Sugarcane Bagasse Plate Making Machine, we’re here to help you. Contact us today!

Sugarcane bagasse tableware Machinery List –

Robotic Integrated Forming Machine, Semi Automatic Forming Machine, Integrated solution for Molded Fiber Packaging, Edge Trimming Machine, Production Molds

In the need for sustainable and eco-friendly alternatives to single-use plastic tableware, bagasse plates have emerged as a promising solution. Bagasse, the fibrous residue left after extracting sugarcane juice, serves as the raw material for manufacturing biodegradable and compostable plates, bowls, and cups. This blog explores the process of making bagasse tableware and highlights the functions and features of various bagasse plate-making machines.

Raw Material For Sugarcane Bagasse Plate Making

Molded Fiber pulp sheets are used as the essential raw material for the production of disposable plates, and they are easily available in the market at highly affordable prices.

The transformation of waste sugarcane bagasse into clear and readily usable Molded Fiber (Disposable) pulp sheets entails undergoing a series of mechanical and chemical stock preparation processes, which closely resemble those employed in the paper manufacturing industry.

The cost of establishing a stock preparation system for Molded Fiber Pulp Sheets is twice as high as that of a Disposable Tableware production line. However, these bagasse pulp sheets are readily accessible in the market at a convenient price, which is why manufacturers of bagasse tableware prefer to utilize them.

Machinery and Systems Required for Disposable Tableware Manufacturing

The manufacturing process of disposable tableware, utilizing sugarcane bagasse as the raw material, requires the integration of numerous auxiliary systems and specialized machinery.

Pulping system

The pulping system serves as the primary method for breaking down pulp sheets and transforming them into slurry.

The Sugarcane Bagasse Tableware Formation Machine requires pulp in slurry form in order to its operational requirement. The forming (pulp molding) machine molds bagasse pulp into a solid tableware structure after passing it through the formation and hot press stations within forming machine. The desired consistency for the slurry is between 0.3 to 0.5% pulp consistency. In the tableware project, the pulping system comprises pulpers, refiners, and pulp storage tanks.

During the pulping process, manufacturers also take additional measures to enhance the properties of the sugarcane bagasse plates. Hence, they add water and oil-resistant chemicals to the pulp slurry to achieve this improvement.

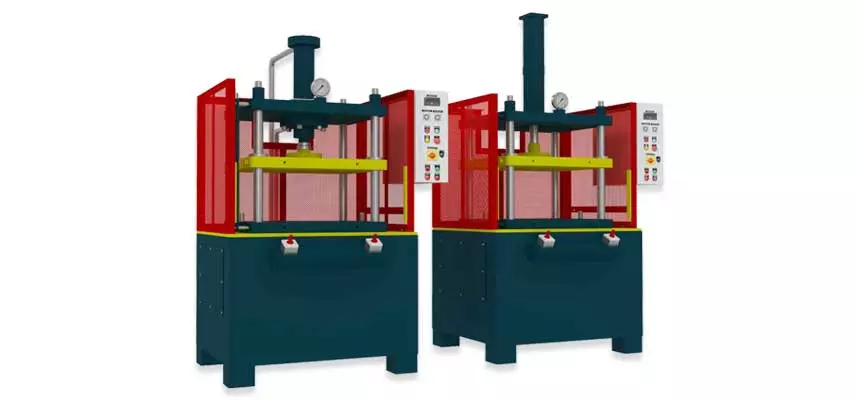

Tableware Forming Machines

The Parason Automatic Tableware Forming Machine employs advanced technology to shape bagasse pulp into sturdy and well-defined plate structure.

The forming machine assembles the molds on the formation station and pours the pulp slurry onto the molds to form a sturdy tableware structure. Additionally, the forming machine connected to auxiliary systems in tableware plants, including Vacuum and Thermic Flued heating systems.

Tableware Trimming Machine

Once the bagasse pulp forms into plates, the next step involves the Tableware Edge Trimming Machine. This machine is responsible for cutting excess material from the bagasse plate products and ensuring consistent sizing according to predefined dimensions.

The trimming process not only enhances the aesthetic appeal of the tableware but also facilitates ease of use for consumers.

Tableware Molds

To produce tableware in different designs of bowls and plates, the manufacturing process requires various designs of tableware molds. It enables to maintain a variety of offerings to your customers as per their needs.

The use of bagasse plate-making machines has revolutionized the production of eco-friendly and biodegradable tableware. By harnessing the potential of bagasse, a byproduct of the sugarcane industry, these machines enable the creation of sustainable alternatives to single-use plastic tableware. The manufacturing process, from pulping to trimming, ensures the production of high-quality, visually appealing and oil and water-resistant tableware.

FAQ ( Sugarcane Bagasse Plate Making Machine)

What are the different sizes of bagasse plates that can be produced?

On the availability of production molds, diverse designs and sizes of disposable bagasse plates can be manufactured.

Click here to explore all production molds Parason Machinery offers

URL – Visit Now

1. What is the production capacity of a bagasse plate-making machine?

A single Tableware Forming Machine can produce a 0.5 TPD of disposable tableware.

In this way a tableware factory with 6 Tableware forming machines can produce daily 3TPD disposable tableware.

2. Can bagasse plates be used in microwave ovens?

Yes, as the bagasse plates are microwave ovens, oil and water-resistant.

3. Are Sugar bagasse plate making machine easy to operate?

All the sugarcane bagasse machines offered by Parason Machinery are manufactured with world-class technology and a can operator can operate it vary easily a providing training.

4. Can bagasse plates be recycled?

As the bagasse tableware is made from a natural source which is sugarcane waste material, it can be recycled in paper mills.

Looking for a reliable partner to set up a Sugarcane Bagasse Plate Making Plant ?

From basic questions to complex compliance inquiries about the Sugarcane Bagasse Plate Making Machine, we’re here to help you. Contact us today!

Parason Robotic Integrated Forming Machine

Enquiry Form

Related Links –

Biodegradable Tableware Making Machine