Low Consistency Cleaner

Working Principles

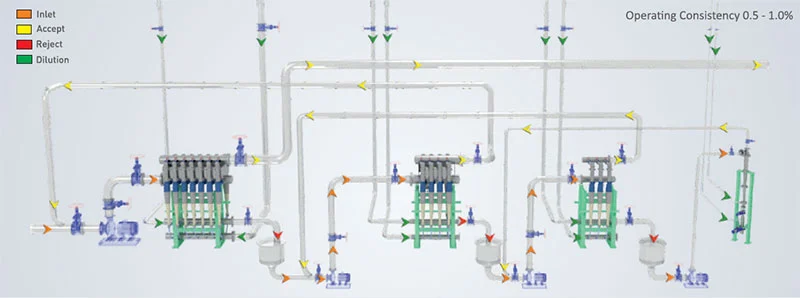

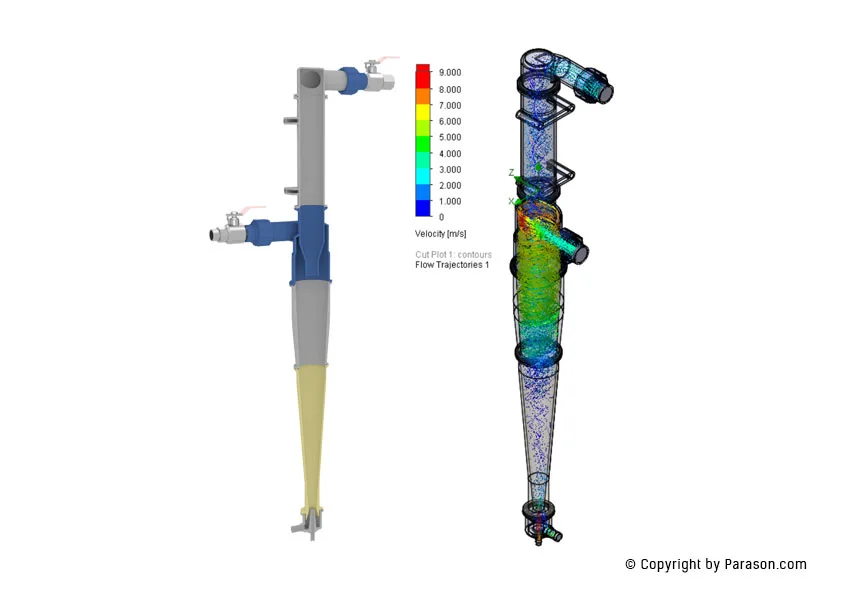

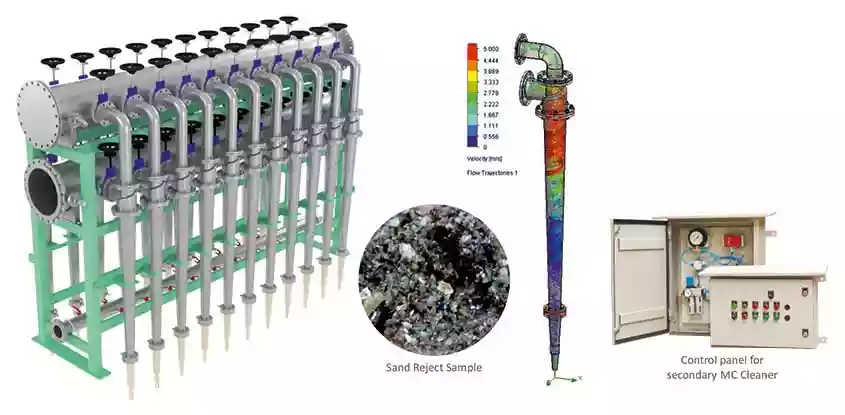

Pulp stock at 0.5 to 1.0% consistency fed through inlet pipe header to the cleaners. The stock enters the tangential inlet which accelerates the stock to downward centrifugal motion. Contaminants like dirt, shives, and specks with high specific gravity are forced to the outer wall of the cone and downward through the reject outlet orifice to reject the header, the reject is again fed to the 2nd stage of cleaners. The cleaned pulp stock rises upward and goes via accept header to the upstream system, at the bottom of cleaners have dilution water headers with individual elutriation line provided to eliminate the fiber losses.

Applications & Unique Features

Efficient removal of contaminants like sand, glass, chips, pins, etc. from the pulp stock

- Efficient removal of impurities like dirt, shives, specks, and light particles

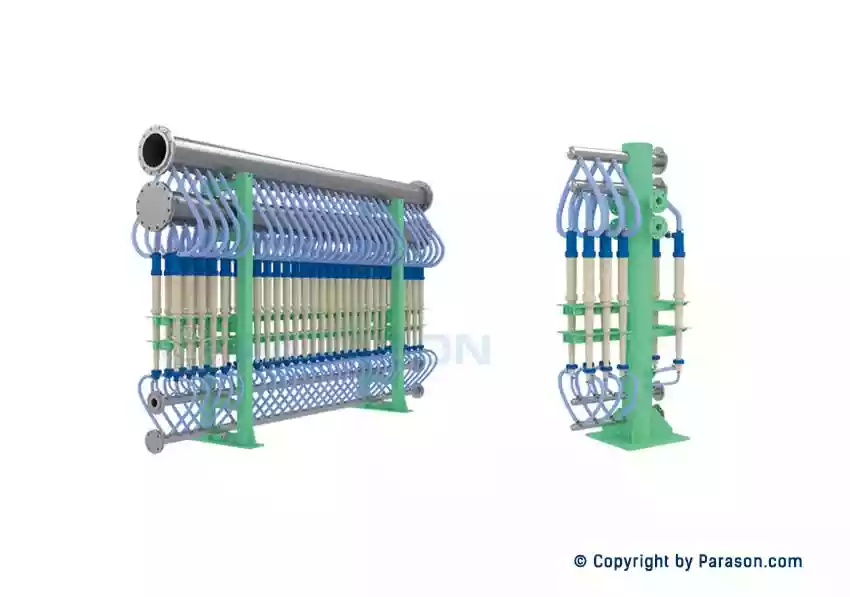

- High wear resistance construction, Bottom ceramic cone

- Improved optical cleanliness of paper due to removal of specks, shives & dirt

- The small cone diameter resulting in outstanding cleaning efficiency

- Proven design for approach flow location

Low Consistency Cleaner

Enquiry Form

RELATED LINKS